Datos de Contacto

UNIT 6, 1/F BLK B NEW TRADE PLAZA 6 ON PING ST SHATIN NT, HongKong, China

34606051359

Hong Kong

1991

Ukraine, Turkey, Mexico, Russia, the Philippines, the African Intellectual Property Organization, New Zealand, Mongolia, Monaco, Kazakhstan, Indonesia, the United Kingdom, the European Union, Taiwan, Bangladesh, Saudi Arabia

AUSTAR is dedicated to serving the life sciences with leading technology and extensive expertise in process technology, applications, and regulatory practices. Helping clients with quality, compliance, and operational excellence, and providing turnkey solutions in equipment, engineering, service, and consumables. Our commitment to these solutions promotes industry progress and creates value.

CONSULTORÍA

INGENIERÍA

INSTRUMENTAL ANALÍTICO

INSUMOS

LABORATORIOS

MÁQUINAS Y EQUIPOS

SERVICIOS

SOFTWARE

SOLUCIONES PARA EL MANEJO DE FLUIDOS

Cleanroom Systems

AUSTAR, introducing the advanced cleanroom technologies from Europe in terms of cleanroom engineering services, produces and constructs pharmaceutical cleanrooms for Italian delta2000 system in China, and is the exclusive agent for the GRP cleanroom products of MRC Company's Dubai factory in China.

Isolator Gloves

AUSTAR isolator gloves are made of chlorosulfonated polyethylene (CSM) and epdm rubber (EPDM), combined with special production processes, and have excellent chemical resistance, as well as excellent mechanical resistance to wear, cutting, tearing and puncture. It can be used on isolators and RABS systems.

Cleanroom Garments Series

The garments can be sterilized for hundreds of times and effectively prevent bacteria, dust, liquid and other contamination from penetrating the clothing surface. They can still maintain good isolation and protection effect even after high temperature cleaning and sterilizing for hundreds of times, so the garments can be cleaned repeatedly and they are durable.

Rapid Transfer Port

Aseptic contained system and sterile material transfer are very important in pharmaceutical production. Rapid Transfer Port (RTP) system has become the standard of pharmaceutical industry. RTP uses various beta components to transfer materials to isolators, filling lines, RABs, biosafety cabinets or clean rooms through alpha ports with interlocking safety mechanisms.

Wet Granulating Equipment

To improve the productivity, operation cost, and EHS condition, AUSTAR integrate the PAT, Containment Technology and Powder Handling experience into the wet granulating/pellet coating technology; with the innovative process practice, which rely on the ability of design, fluid tech, automatic control, process, validation and project management in AUSTAR.

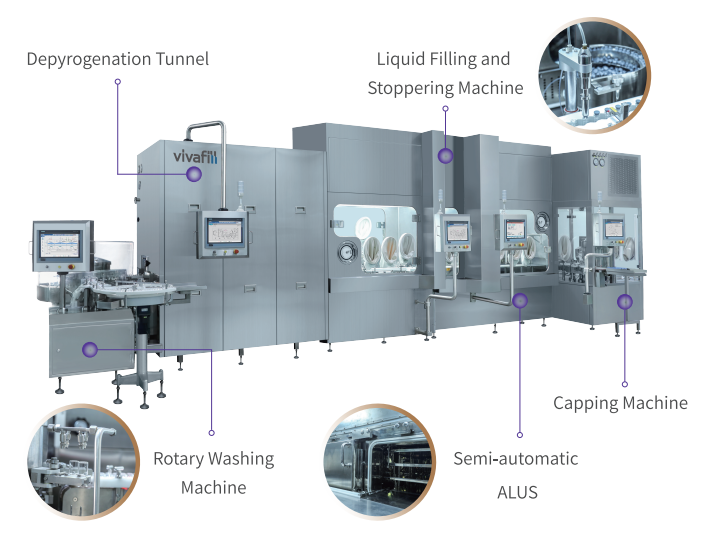

vivafill Compact Filling Line

Based on its strategic cooperation with ROTA from Germany and M&O Perry from the United States, AUSTAR provides clients with customized sterile filling solutions for liquid and powder. At the same time Austar, by integrating its freeze-dryer and automatic loading and unloading device, can provide clients with highly integrated sterile packaging system for lyophilized powder.

Freeze Dryer

AUSTAR is committed to providing clients with high-performance and intelligent LYOCORE freeze-dryer which is designed and manufactured according to European quality standards based on the concept of QbD (quality by design). The freeze-dryer is suitable for commercial freeze-drying production of vial and panel-packed APIs.

Pure Steam Generator

he Finn-Aqua TC series pure steam generator is designed in accordance with the requirement of cGMP, which can produce high quality PS superior to the PS requirements of pharmaceutical industry and biological industry in the USA and EU. The TC series PS generator can realize multi-effect distillation with the heat from the steam.

Multiple Effect Water Still

The Finn-Aqua TC series multi-effect water distiller is designed in compliance with the requirements of cGMP, which can produce high quality WFI superior to the WFI requirements for the pharmaceutical industry and biological industry in the USA and EU. The TC series distiller can realize multi-effect distillation with the heat from the steam.

Automatic Visual Inspection Solution

Mainly used for automatic visual inspection of visible particles and cosmetic defects of ampoules, oral liquid, vials( liquid injections and freeze-dried powder injections), cartridge injections (water-like and suspension), pre-filled syringes, eye drops and other products.